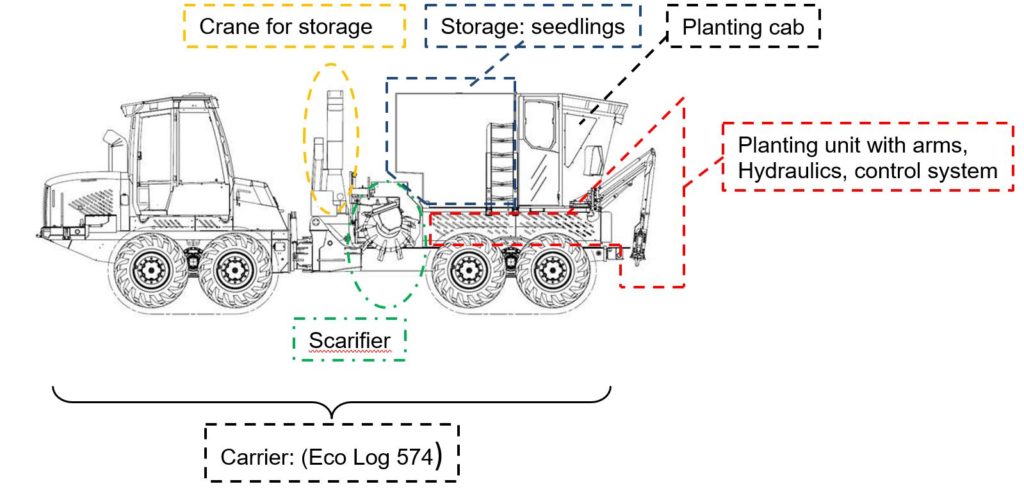

Carrier

The PlantMax unit is mounted on a forwarder and is compatible with many different makes and models, such as Eco Log 574, Ponsse Buffalo or a similar machine with matching specification.

Planting Unit

The heart of the machine is a frame, bolted to the carrier, that we call the planting unit. To this frame the planting arms are attached and inside the frame all the necessary hydraulic valves, air valves and control units are mounted as well as a water tank.

Scarifier/subsoiler

For cultivating the ground we use a disc-scarifier, a MidiFlex. The Midiflex has the advantage that it can be mounted between the front and the rear boggie, and thus the rear boggie will run over to prepared ground and compact, making it ready to plant immediately.

PlantMax can also be equipped with our in-house developed subsoiler as an alternative to the scarifier.

Planting cab

The planting device of PlantMax is not yet automated, so feeding plants from the cartons in the seedling storage to the planting arms is done manually in specially designed “cups” that take the seedling to the planting arm.

The operator in the rear cab is responsible for feeding seedlings to the cups that feed the planting arms and also for evaluating the planting quality.

Seedling storage

Storage for boxes of seedling. Can hold 15-20.000 seedlings, depending on size of seedling.

Crane for the storage

The crane is intended to be used when switching seedling storage on the PlantMax. Naturally, this could be done by the standard crane of the forwarder, but due to Swedish height restrictions on the road, we can not leave the standard crane on the machine and have therefore replaced that crane with a crane for road trucks that folds up within the height limits. In some markets the standard crane might be used.

PlantMax X3 technical specification

Main

Type: Two row tree planter

Weight (typical): 4500 kg (narrow configuration, no scarifier/subsoiler)

Cab: ROPS/FOPS compliant safety cab. 12 mm polycarbonate windows

Climate: Heating, ventilation, air conditioning

Electronic system: 24V

Controller system: CAN-based mobile controller system

Hydraulics: Load sensing pressure compensated. Req. flow/pressure 120L/min 130 bar

Planter

Performance: 3000 seedlings/h (max technical)

Planter width (C-C): Narrow: 2250, 2480, 2710 Wide: 2940, 3170, 3440 (mm)

Width adjustment: +/-8° (approx. +/- 220 mm (110 mm/side))

Planting depth: 3 different tips (S, M, L); 8 planting hardness levels

Compacting: 2 different spades; 8 compactor hardness levels

Seedling spacing: Adjustable, automatic adjustment for missed planting attempts

General

Fuel tank: Extra fuel tank for carrier 235 litres

Water tank: 320 litres

Seedling storage: 3 floor storage, >8000 seedlings (depending on size and container)